Inventory management for your online business can be a bit tricky. Orders come flying in, items should be shipped out, and you must try to monitor what you have all through inventory.

Consumer satisfaction is tremendously important to your business, so ensuring orders are fulfilled and shipped on time should be your top priority. You need a solution that holds the entirety of your inventory under control and guarantees you replenish in time.

Enter Just in Time (JIT) inventory, a training that limits inventory and overabundance items, so your business just has what is required close by.

While manufacturing organizations like Toyota have invested a great deal of energy and cash on perfecting this procedure, it isn’t generally as effectively recreated for ecommerce organizations.

Here’s a complete guide on what JIT inventory implies and the ways in which it can work for your business.

What is the Just in Time (JIT) inventory?

JIT is a technique for supply chain management that intends to reduce expenses, increment proficiency, and waste by accepting goods when they are required. It viably implies having enough inventory accessible to satisfy client needs, however close to simply enough, so you have to reserve the rest of the stuff, considering that point.

History of Just in Time inventory

The Just in Time inventory method initially originated in Japan and is otherwise called the Toyota Production System, as the car manufacturer received the Inventory management system during the 1970s.

Many believe that JIT has its roots in Japan’s shipyards because of Japan’s condition of cash post-war. There was a lack of standard assets and space for substantial industrial facilities and inventory.

Later, at the beginning of the 1980s, JIT was implemented in Western nations.

Is Just in Time worth it?

Viably implementing a JIT Inventory management system can prompt numerous favorable circumstances that empower makers to process inventory rapidly and proficiently. Notwithstanding, there are likewise a few drawbacks to JIT. Indeed, even the smallest disturbance can prompt tremendous issues.

Pros of JIT inventory

JIT has a few advantages to an organization’s creation procedure, including:

- Reduced storage costs: Due to the way that stock is delivered or obtained at a sudden announcemet, there is no compelling reason to have extra or unsold inventory that occupies valuable inventory extra space. Storage space is costly, which can likewise prompt high inventory carrying costs.

- Improved communication: JIT systems are just compelling when communication is clear. To guarantee issues don’t happen, and the inventory system runs efficiently, groups need to convey consistency.

- Less waste: Since JIT systems depend on client requests and just production what has been as of late acquired, it dispenses with the volume of waste and excess inventory.

- Smaller inventory investments: As per the trends online purchase has, companies spend a little measure of cash on raw materials since they just purchase the number of assets they have to deliver orders – that’s it and nothing less and nothing more. Inventory is regularly the highest cost for organizations, and JIT decreases the need to arrange enormous mass inventory clumps that will prompt item lounging around for some time.

Cons of JIT inventory

While JIT can have numerous points of interest, there are likewise a few drawbacks, which include:

- Hard to execute: Companies that implement a JIT inventory system will rapidly comprehend there is no place for the mistake. Thus there is an opportunity they’ll encounter challenges and difficulties before they get it right. Inventory control is hard to oversee, particularly for quickly growing organizations.

- Greater danger of supply chain failure: A delay in getting inventory or a breakdown in machinery could be adverse to an organization’s inventory network and cause huge issues.

- More planning: In request to do JIT right, organizations must have accurate demand forecasts as well as real-time inventory tracking and client purchasing insights. A little miscount could largely affect all the business activities.

- Stockouts are more probable: Since the JIT system calls just to have quite recently enough inventory, it’s feasible for organizations to run out if there is an impromptu flood in orders, making order fulfillment delayed.

JIT Inventory for online business stores

JIT inventory systems are often utilized in assembling; however, there is the probability of using the JIT strategy for eCommerce stores.

By applying JIT, you could reduce inventory levels inside your fulfillment center or inventory room and just hold a particular measure of inventory to satisfy orders as per the client request. This may likewise decrease the expenses of crude materials, as you would just need to deliver what is requested.

Implementing this Inventory management system would empower your internet business store to lessen the opportunity of out of date inventory, potentially decrease generation lead times, and decrease the degree of interest in working capital.

Strict control

Ecommerce stores should manage their production network the board as much as they can to arrive at any kind of effectiveness with JIT. They have to stay over orders and inventory to successfully control their generation procedure following JIT systems.

A Greater requirement for information

Warehousing and inventory forecasting data are incredible on the off chance that you use it effectively. Since JIT is dependent on your past organic market, you’ll need constant information to quantify your needs or future inventory.

Utilizing an electronic data solution (EDI) would empower ecommerce stores to oversee inventory, improve proficiency, and control edges. EDI likewise enables stores to gather and transmit data precisely to improve anticipating expectations. The solution will consequently arrange new inventory to recharge inventory levels once they hit a specific edge with the deftness and speed expected to fulfill buyer and retail needs.

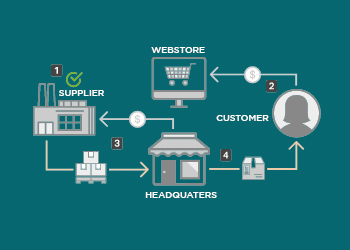

THE PROCESS

The JIT fulfillment model is sufficiently direct, yet it’s in contrast with different models. It is the way that item is bought later simultaneously, not toward the beginning. Here is how it works.

- Source suppliers

- Get yourself a few suppliers conveying products you need to sell. Check them and vet them.

- Make a deal

- Since you’re a branding and online marketing genius, an order is made on your site.

- Buy item

- Presently you should buy the items in a specific order and have them shipped your way.

- Fulfill the request

- When they’ve shown up, take those items, bundle them for the order, and ship it off to the client.

RELATIONSHIPS ARE EVERYTHING

There’s an explanation for JIT isn’t excessively normal, however. It’s operational over-burden. A fulfillment workflow that works as expected is perfect. However, it’s hard to accomplish through JIT because purchasing items turn out to be one more advance in the fulfillment procedure that is amazingly dependent on your providers.

Absence of Control

Your relationship with providers is significant in any fulfillment model, yet it’s basic with JIT. With regards to your item, it’s in the nick of time, not the progress of time. The assumption here is that your sellers are accessible upon request — they’ll generally have an inventory of items to fulfill your need in substantial time. You depend altogether upon them to rapidly sell and ship you the item that you’ll at that point send to the client.

Furthermore, because you’re standing by to get an item before you can transport it to clients, conveyance time — a factor that is tremendously compelling on a customer’s choice to buy — will, in general, be longer. That can turn into a significant hindrance to making on the web deals, and it’s brought about by your dependence on the provider.

To make matters worse, providers are, in all likelihood offering items to different organizations that may be buying more massive amounts of the products at once. That conceivably undermines your chances of getting the products when you need them, and the provider certainly thinks unmistakably more about their business than yours.

The entirety of this demonstrates your supply-side relationship is significant. You should discover a provider that meets your requirements. Here are a few inquiries to remember as you pick them:

- Are there different approaches to reach this merchant? Is it true that they are informative and simple to contact?

- Does this vendor ship orders rapidly and dependably? Would I be able to depend on them to deliver on schedule?

- Are they straightforward with their item volume so that I can get ready for them is not able to fulfill my needs?

- Is a Service Level Agreement (agreement of service desires between two gatherings) debatable?

Vetting suppliers likewise implies giving their sites, valuing, reviews, even their offices a look if possible.

Conclusion

Just in Time inventory systems can aid ecommerce stores to lessen waste, space, and expenses. Notwithstanding, your store will likewise be as coordinated as could reasonably be expected and have the capacity to take care of a shorter than normal production cycle.

While JIT is regularly utilized concerning Inventory management, similar standards can be applied to different areas of the supply chain.